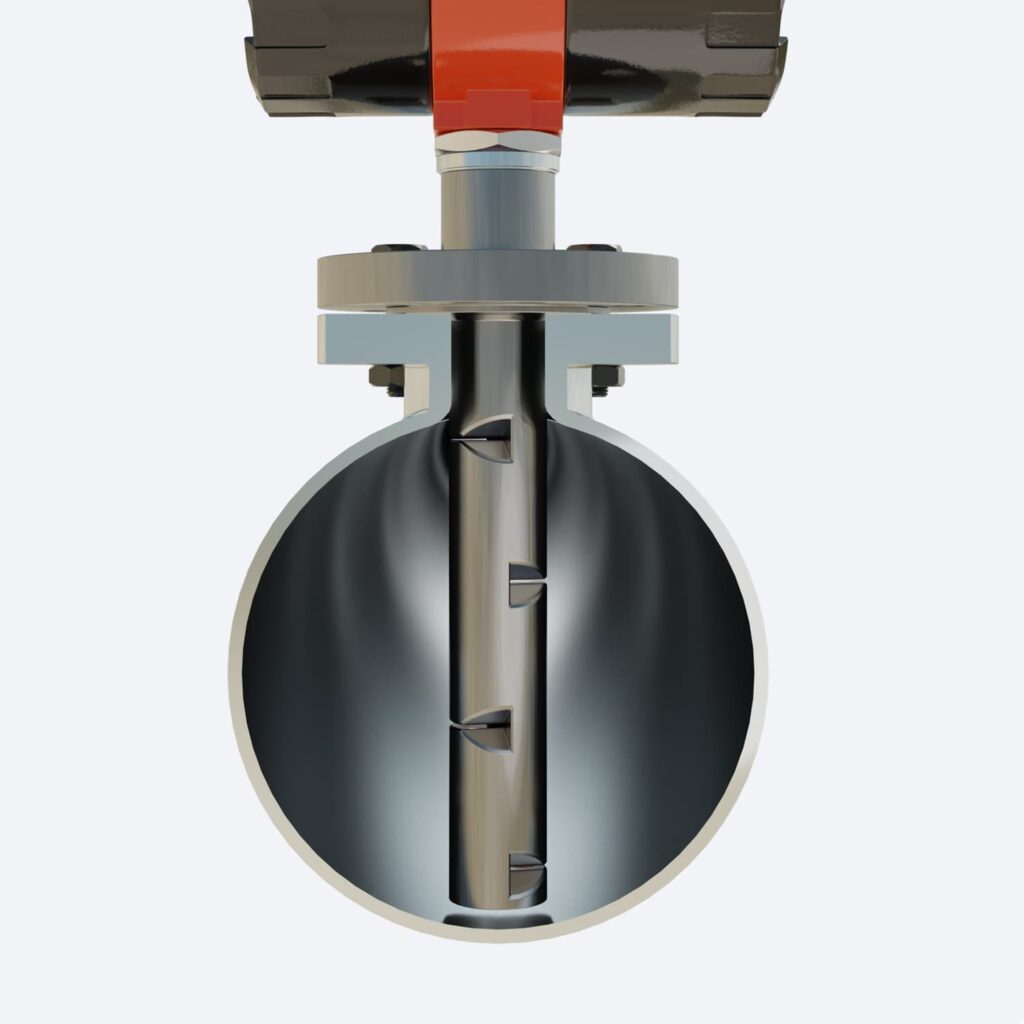

The Poseidon water-cut meter features patented optical technology that delivers unmatched accuracy and reliability across 2 and 3 phase flow conditions. Multiple sensing points profile the water distribution in the pipe thus maintaining measurement accuracy in changing flow regimes and quasi-stratified flow.

The novel optical arrangement has been designed to prevent films and blockages on the optical windows to maintain accuracy at all times. The sensor has an automated diagnostic feature to detect and alert the operator of any optical issues and with multiple sensing points there is always measurement redundancy.

The probe form factor makes integration easy, quick and cost effective. The integrated temperature measurement allows for installation into existing thermowells reducing the barriers to entry and cost of installation.

0-100% WC range & not affected by inversion point

Excellent performance in wet gas conditions from 90-99.9%

Novel design to prevent fouling with automated optical diagnostics

Measurement unaffected by salinity

Easy calibration with no PVT data required

Maintains accuracy in changing flow regimes and quasi-stratified flow

Measurement unaffected by hydrate inhibitors, solids & emulsions

| Specifications | |

|---|---|

| WC measurement range | 0-100% |

| WC measurement accuracy | <± 2% WC across entire operating envelope |

| WC measurement resolution | ± 0.1% |

| GVF Application range | 0-99.9% |

| Built in temperature sensor | Calibrated Pt100 Class A temperature sensor at probe tip. |

| Output update frequency | Adjustable averaging period to suit any flow dynamic; fast water-cut transients can be captured. 1 output update per 10 seconds (0.1 Hz) by default. |

| External input requirements | None - there is no requirement for PVT, pressure temperature, conductivity or density |

| Water salinity effect | Not effected by salinity or water chemistry |

| Hydrate inhibitors effect | Not effected by MeOH, MEG, DEG, TEG. |

| Self diagnostics | Multi-parameter fault detection and reporting. Automatic continuous optical window condition monitoring. |

| Installation | |

|---|---|

| Form factor | Flanged probe. |

| Orientation | Any; vertical, horizontal or inclined. Rotatable display. |

| Flow regime | Any; including multiphase or two-phase flow, emulsions, mist flow, transient slug flow, partially stratified flow. |

| Location | Onshore or offshore topside, upstream or downstream of separator, installation can make use of existing thermowell or sampling probe location. |

| Process pipe size | 3” through to 24”. |

| Mechanical | |

|---|---|

| Wetted materials | SS316L or Hastelloy C276, synthetic sapphire. Optional tungsten-carbide cover sleeve for erosion mitigation. |

| Main meter body | SS316L or marine-grade epoxy coated aluminium or customer-specified paint and application process. |

| Process connection | 2” ASME/ANSI B16.5 flange #300, #600, #900, #1500 RF, or 2” RTJ flange, or customer-specified. |

| Operating pressure | As determined by flange type, up to 3625 PSI (250 bar) cold working pressure. |

| Operating temperature | Ambient -40 ˚C (-40 ˚F) through to +60 ˚C (158 ˚F). Process fluids up to +150 ˚C (302 ˚F). |

| Electrical | |

|---|---|

| Power requirement | <10W typ. Other power options (e.g. battery pack, solar, available on request). |

| Voltage | 10-36 V DC, 24 V DC typ. |

| Communications | Standard: 2x 4-20 mA HART, 1x RS232, 1x Modbus RTU over RS485. Optional: Modbus TCP over Ethernet, Bluetooth (for configuration), other protocols available on request. |

| Compliance | |

|---|---|

| Functional | 100% unit test as part of factory acceptance testing. Optional certificate from testing at NEL AMF. Optional testing to customer-specified conditions and environment. |

| Safety | Hazardous location approvals include UKCA (UK), ATEX (Europe), CSA (Canada), NEC (USA), EAC Ex (Eurasia), IECEx (International) for operation in Zone 1 designated locations. Double-sealed sensing head from process fluids to UL 122701. Compliant with NACE MR0175/ISO 15156 for sour service without limit on the H2S partial pressure up to the maximum process fluid temperature of +150 ˚C (302 ˚F). Compliant with ASME PTC 19.3 TW-2016 thermowell code. |

| Ingress | IP66 – complete protection against dust and strong water jets. |

The price is dependant on the configuration you require but we set out to develop and build the most cost effective water-cut meter in the Oil and Gas sector so please contact us for a quote.

Yes, the sensor has been tested in wet gas conditions up to 99.9% GVF.

Yes, the water-cut sensor has a Pt100 Class A temperature sensor integrated so you can replace an existing thermowell and get a water-cut measurement as well as temperature.

No, our multiple sensing points and novel analysis algorithms can calculate the water-cut in any flow regime.